Understanding Diamond Blades

Diamond blades are the cornerstone of the cutting industry, designed to offer precision and efficiency in cutting hard materials such as tile, stone, and concrete. Their unmatched durability and cutting capability stem from the diamond, the hardest material known, embedded in their edge.

Composition and Types

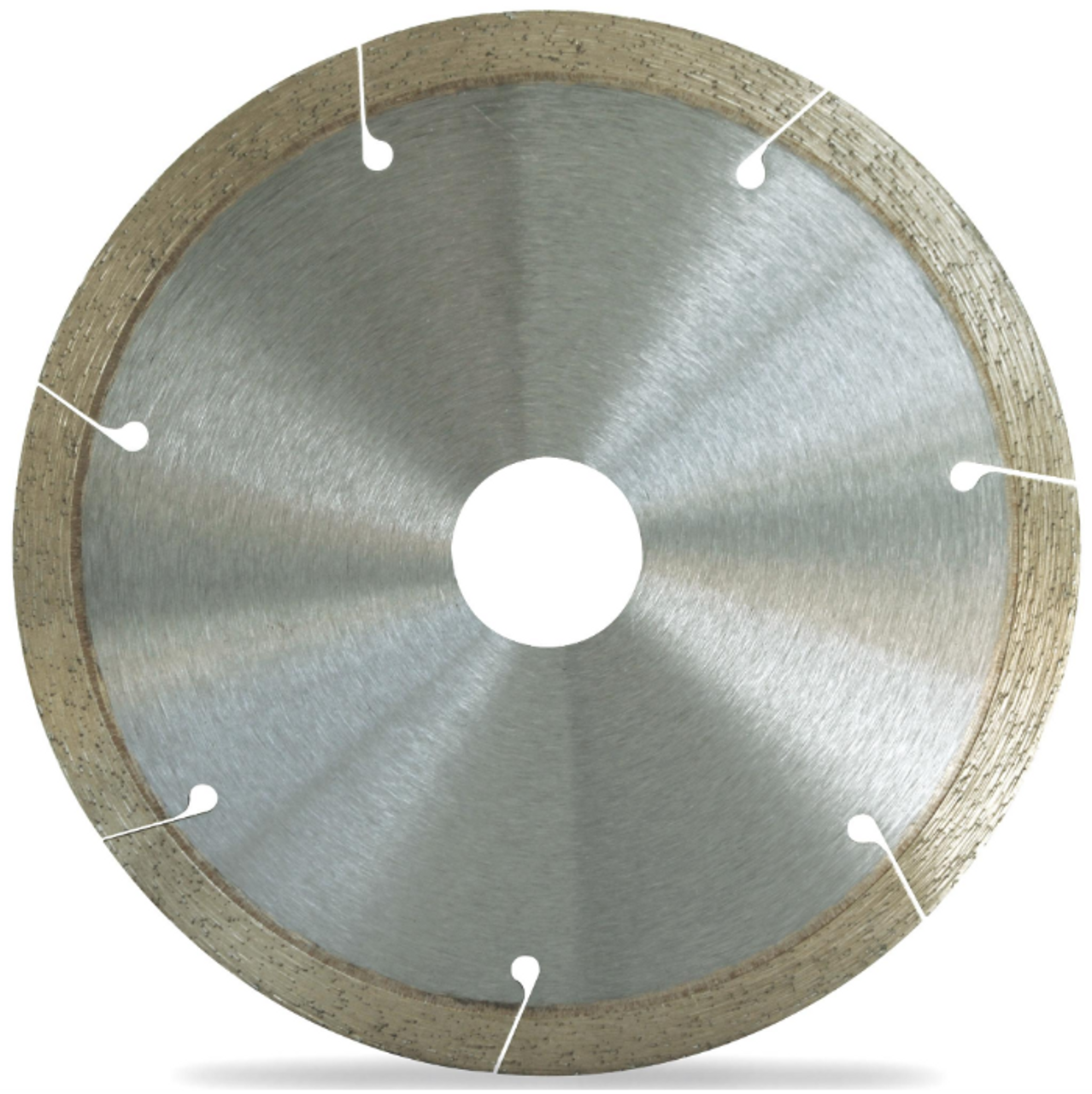

A diamond blade's effectiveness lies in its construction. These blades consist of a steel core and a diamond segment (the cutting part) bonded to the perimeter. The diamonds are mixed with a metal matrix to hold them in place. As the blade cuts, the matrix wears away, exposing new, sharp diamond edges. This self-sharpening feature ensures consistent performance over the blade's life.

There are various types of diamond blades tailored for different materials and cutting conditions. For instance, blades designed for cutting through tile and stone may differ in diamond grit size and matrix composition to optimize for smooth cuts and minimize chipping.

Choosing the Right Blade

Selecting the correct diamond blade for a project involves considering the material to be cut and the type of cut desired (wet or dry). Wet cutting blades, designed for use with water, reduce dust and heat, extending the blade's life and improving the cut quality. The specifications of a blade, such as the diamond size, concentration, and matrix hardness, are tuned to match specific cutting needs, whether it's for delicate tile work or robust stone cutting.

Understanding Diamond Grit and Bond

The diamond grit size affects the cutting speed and finish. Smaller grit sizes result in smoother finishes, while larger grits cut faster but with rougher finishes. The bond of the diamond segment determines how fast the diamonds are exposed. A softer bond wears down quicker, suitable for hard materials, ensuring new diamonds are exposed at the right rate to maintain cutting efficiency.

Wet vs. Dry Cutting Blades

While this guide focuses on wet cutting, it's crucial to note the differences between wet and dry cutting blades. Wet cutting blades typically have a softer bond, optimized for use with water to prevent overheating and prolong the blade's life. Dry cutting blades, on the other hand, are designed to dissipate heat without water, suitable for jobs where water use is impractical.

By understanding these aspects of diamond blades, users can make informed decisions to match the right blade with their specific cutting tasks, ensuring optimal performance and results.

Maintenance and Safety Tips

Proper maintenance and safety are pivotal for enhancing the performance and lifespan of diamond blades, as well as ensuring operator safety during cutting operations.

Maintenance Tips

§Blade Cleaning: Regular cleaning of the blade removes debris that can affect cutting performance. Use a soft brush and clean water to remove any material buildup on the blade.

§Inspection: Before and after each use, inspect your diamond blade for any signs of wear, damage, or segment loss. This ensures that the blade is safe to use and helps in identifying when a replacement is needed.

§Storage: Store the diamond blades in a dry, secure place to prevent corrosion and damage. Avoid stacking heavy items on the blades to prevent warping.

Safety Tips

§Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety goggles, gloves, ear protection, and a dust mask when cutting dry to prevent inhalation of dust particles.

§Equipment Safety: Ensure that the cutting equipment is in good working condition. The blade should be correctly installed, and the water feed (for wet cutting) should be functioning properly to prevent overheating.

§Work Area: Keep the work area clean and well-ventilated. For wet cutting, ensure there is adequate drainage to avoid slipping hazards.

§Handling and Operation: Handle the diamond blade with care, avoiding impacts that can cause chipping or breakage. Follow the manufacturer's guidelines for operating speed and pressure to avoid overloading the blade.

By adhering to these maintenance and safety guidelines, users can significantly reduce the risk of accidents and enhance the efficiency and lifespan of their diamond blades, ensuring smooth and safe cutting operations.

Advanced Tips for Professionals

Here are some advanced tips for professionals looking to refine their cutting skills:

§Optimizing Water Flow: When wet cutting, adjusting the water flow to match the material hardness and blade type can significantly enhance the cutting process. Too little water might not cool the blade efficiently, while too much can create a messy work environment and reduce visibility.

§Blade Dressing: Over time, diamond blades may become glazed or underperform due to overheating or cutting soft materials. Dressing the blade by making cuts in abrasive materials can expose new diamonds, restoring the blade's cutting ability.

§Variable Speed Cutting: Using variable speeds based on the material being cut can improve the quality of the cut and extend the blade's life. Harder materials typically require slower speeds to reduce blade wear, while softer materials can be cut faster.

§Precise Material Handling: For intricate cuts, especially in delicate materials like porcelain or marble, using a clamping system to hold the material firmly can reduce the chances of chipping and ensure cleaner cuts.

Implementing these advanced techniques requires practice and a deep understanding of both the materials being cut and the equipment used. By continuously learning and adapting, professionals can achieve superior results and maintain a competitive edge in their work.

Wet cutting with diamond blades combines precision with efficiency. By understanding the proper techniques and maintaining safety standards, users can achieve professional-grade results in their cutting projects.

Get the Perfect Cut with Our Diamond Blades

Elevate your cutting projects with our top-of-the-line diamond blades for tile and stone. Whether you're a professional contractor or a DIY enthusiast, our tile blade options for grinder provide unparalleled precision and durability.

Don't settle for less —choose our diamond blades for your next project and experience cutting like never before.